EDM graphite

EDM graphite is a purpose-engineered graphite material developed specifically for electrical discharge machining, where precision, surface quality, and electrode stability directly affect machining efficiency and mold accuracy. In real EDM production, graphite grade selection often matters more than machine parameters themselves.

Product Description

EDM graphite is manufactured from high-purity carbon raw materials using controlled molding or isostatic pressing, followed by high-temperature graphitization. Compared with general industrial graphite, EDM grades are optimized for fine grain structure, uniform density, and predictable electrical behavior.

The goal is simple: produce electrodes that machine cleanly, spark consistently, and wear in a controlled manner. When done right, EDM graphite becomes a productivity tool rather than a consumable headache.

Core Performance Characteristics

Fine and Uniform Grain Structure

EDM graphite typically features grain sizes ranging from 3 μm to 15 μm, depending on grade. Finer grains support:

Sharper edge definition

Improved surface finish on workpieces

Reduced risk of edge chipping during machining

For complex cavities and detailed molds, grain size often becomes the deciding factor.

Stable Electrical Conductivity

Consistent resistivity ensures uniform spark distribution during EDM. This leads to:

Predictable material removal rates

Reduced abnormal discharge

More consistent cavity geometry

Actually, unstable conductivity is one of the most common hidden causes of uneven electrode wear.

Controlled Wear Behavior

EDM graphite is designed to wear gradually and evenly. Compared with copper electrodes, graphite offers:

Lower tool wear in many applications

Easier compensation in CNC programs

Better performance in deep or narrow cavities

In finishing operations, predictable wear saves more time than raw cutting speed.

Excellent Machinability

EDM graphite machines easily using standard CNC equipment. It allows:

High feed rates

Minimal tool wear

Clean edges without burrs

This makes electrode production faster and more cost-effective, especially for high-volume mold shops.

Common EDM Applications

Injection Mold Electrodes

Used for producing detailed cavities in plastic injection molds with tight tolerance requirements.

Die Casting Mold Electrodes

Suitable for large electrodes where dimensional stability and wear consistency are critical.

Precision Tooling and Inserts

Applied in high-accuracy tooling where surface finish directly impacts final product quality.

Micro-EDM and Fine Detail Work

Ultra-fine grain grades support sharp corners and small radii in micro-features.

Typical Technical Ranges (Reference)

| Property | Typical Range |

|---|---|

| Grain Size | 3–15 μm |

| Density | 1.75–1.90 g/cm³ |

| Electrical Resistivity | Low, uniform |

| Flexural Strength | High for graphite |

| Ash Content | Very low |

Exact values depend on grade selection.

Grade Selection Guidance

EDM graphite is not one-grade-fits-all. In practice:

Roughing electrodes favor coarser grain, higher strength grades

Semi-finishing balances strength and surface quality

Finishing electrodes require ultra-fine grain for best detail

Suppliers such as Gotrays typically offer multiple EDM graphite grades so shops can match material to machining stage instead of over-specifying everything.

Handling and Machining Notes

Use proper dust extraction—graphite dust is fine and persistent

Dedicated tools help maintain edge quality

Avoid impact loading to prevent micro-cracks

Store electrodes carefully after machining

Actually, poor handling ruins more EDM electrodes than poor material choice.

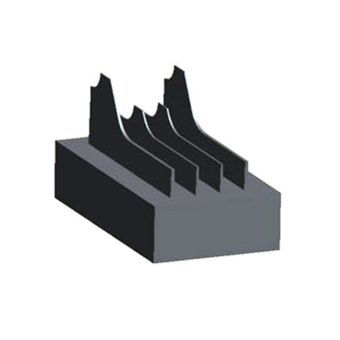

Packaging and Supply

EDM graphite is commonly supplied as:

Precision-cut blocks

Oversized blanks for CNC machining

Custom dimensions upon request

Protective packaging is used to prevent edge damage during transport.