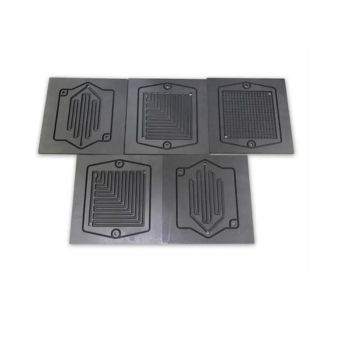

Graphite bipolar plate

A graphite bipolar plate is a core functional component used in fuel cells and electrochemical energy systems, responsible for current collection, gas distribution, and thermal management. Its material quality and structural design directly affect system efficiency, durability, and long-term operating stability.

Product Description

Graphite bipolar plates are manufactured from high-density graphite materials through precision molding, isostatic pressing, or compression forming, followed by machining of flow channels and surface finishing. Compared with metal bipolar plates, graphite plates offer superior corrosion resistance and electrochemical stability, especially in harsh acidic environments.

In practical fuel cell operation, graphite bipolar plates provide a balanced solution between performance reliability and proven material behavior, which is why they remain widely used despite the emergence of metal alternatives.

Core Functional Roles in Fuel Cells

A graphite bipolar plate performs multiple tasks simultaneously:

Conducts electrical current between adjacent cells

Distributes reactant gases (hydrogen, oxygen, air) through flow channels

Separates anode and cathode compartments

Manages heat and removes excess water from the cell

Because one component carries so many responsibilities, material selection is critical.

Key Material Advantages

Excellent Electrical Conductivity

Graphite offers low contact resistance and stable conductivity, ensuring efficient electron transfer across the fuel cell stack. This directly supports higher power output and reduced energy loss.

Outstanding Corrosion Resistance

In proton exchange membrane (PEM) fuel cells and other electrochemical systems, the operating environment is acidic and humid. Graphite remains chemically stable under these conditions, unlike many metals that require surface coatings.

Actually, avoiding coating degradation is one of the biggest reasons graphite is still preferred in long-life systems.

Thermal Stability and Heat Distribution

Graphite bipolar plates provide good thermal conductivity, helping dissipate heat evenly across the stack. This reduces local hot spots and supports consistent cell performance during continuous operation.

Dimensional Stability

High-quality graphite plates maintain shape and flatness under compression and thermal cycling, which is essential for maintaining proper sealing and contact pressure within the stack.

Typical Technical Characteristics (Reference)

| Property | Typical Range |

|---|---|

| Density | 1.75–1.90 g/cm³ |

| Electrical Resistivity | Low, stable |

| Gas Permeability | Extremely low |

| Operating Temperature | Up to ~200°C (PEM systems) |

| Corrosion Resistance | Excellent in acidic media |

Exact values depend on graphite grade and manufacturing method.

Common Applications

Hydrogen Fuel Cells (PEMFC)

Used extensively in fuel cell stacks for stationary, mobile, and backup power systems.

Electrochemical Energy Devices

Applied in redox flow batteries and other electrochemical reactors where corrosion resistance is essential.

Research and Pilot Systems

Preferred in laboratory and pilot-scale fuel cell development due to predictable behavior and ease of machining.

Design and Machining Options

Graphite bipolar plates can be supplied with:

Single-serpentine, multi-serpentine, or parallel flow channels

Customized channel depth and width

Machined manifolds and sealing grooves

Surface treatments to reduce contact resistance

Precise machining is critical, as flow field design strongly influences gas distribution and water management.

Quality Control and Consistency

Key quality factors include:

Density uniformity

Flatness and thickness tolerance

Channel accuracy

Electrical and gas-tight performance

Manufacturers such as Gotrays typically support custom designs and batch consistency, which is important for customers scaling from prototype to production.

Packaging and Handling

Graphite bipolar plates are packed individually or in layered protective packaging to prevent edge damage and surface chipping. Clean handling and dry storage are recommended prior to assembly into fuel cell stacks.