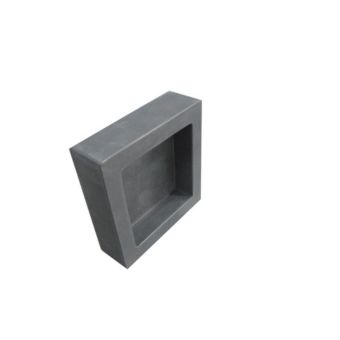

Graphite box

A graphite box is a high-temperature containment and support component used for holding, shielding, and transporting materials during thermal processing. In furnace operations where temperature stability, atmosphere control, and material cleanliness are critical, graphite boxes provide a reliable and flexible solution that outperforms most metallic or ceramic alternatives.

Product Description

Graphite boxes are manufactured from high-density graphite or fine-grain graphite through precision machining and high-temperature graphitization. They are typically designed as open or lidded rectangular containers, with dimensions and wall thickness customized to suit specific furnace chambers and process requirements.

Unlike simple trays or plates, a graphite box creates a controlled micro-environment for parts, powders, or components during heating. This added protection often improves yield and process consistency, especially in vacuum and inert-gas systems.

Key Performance Advantages

Excellent High-Temperature Stability

Graphite boxes maintain structural integrity at temperatures exceeding 1,000–2,000°C in vacuum or inert atmospheres. They do not melt, soften, or creep under prolonged heat exposure, ensuring consistent geometry over multiple thermal cycles.

This stability is essential when precise part positioning must be maintained.

Superior Thermal Shock Resistance

Modern furnaces often use rapid heating and cooling profiles. Graphite’s low thermal expansion allows graphite boxes to tolerate these temperature changes without cracking or warping, unlike many ceramic containers.

Clean and Non-Reactive Behavior

Graphite is chemically inert to most metals, ceramics, powders, and advanced materials. This minimizes contamination and unwanted reactions during sintering, heat treatment, or material synthesis.

Actually, for high-value or functional materials, contamination control is often the primary reason graphite boxes are chosen.

Uniform Heat Distribution

Graphite’s good thermal conductivity helps distribute heat evenly within the box. This promotes uniform processing conditions, reducing temperature gradients that can cause deformation, incomplete sintering, or inconsistent material properties.

Typical Applications

Vacuum and Inert-Gas Furnaces

Used to hold parts or powders during sintering, brazing, and heat treatment.

Powder Metallurgy and Advanced Ceramics

Applied as containers for compacts and formed parts during high-temperature processing.

Battery and Energy Materials

Used in thermal treatment of cathode, anode, and functional powders.

Semiconductor and Electronic Materials

Suitable for clean, high-purity processing where atmosphere control is critical.

Laboratory and Pilot-Scale Furnaces

Common in R&D environments for controlled and repeatable thermal cycles.

Design and Customization Options

Box Structure

Graphite boxes can be supplied as:

Open-top boxes

Boxes with matching graphite lids

Multi-compartment designs

Custom internal supports or partitions

Wall thickness and reinforcement are optimized to balance strength, weight, and thermal performance.

Graphite Grade Selection

Depending on operating conditions, customers may select:

Molded graphite for cost-effective general use

Fine-grain graphite for improved surface stability

Isostatic graphite for high uniformity and precision

High-purity graphite for contamination-sensitive processes

Choosing the correct grade usually has a greater impact on service life than increasing wall thickness alone.