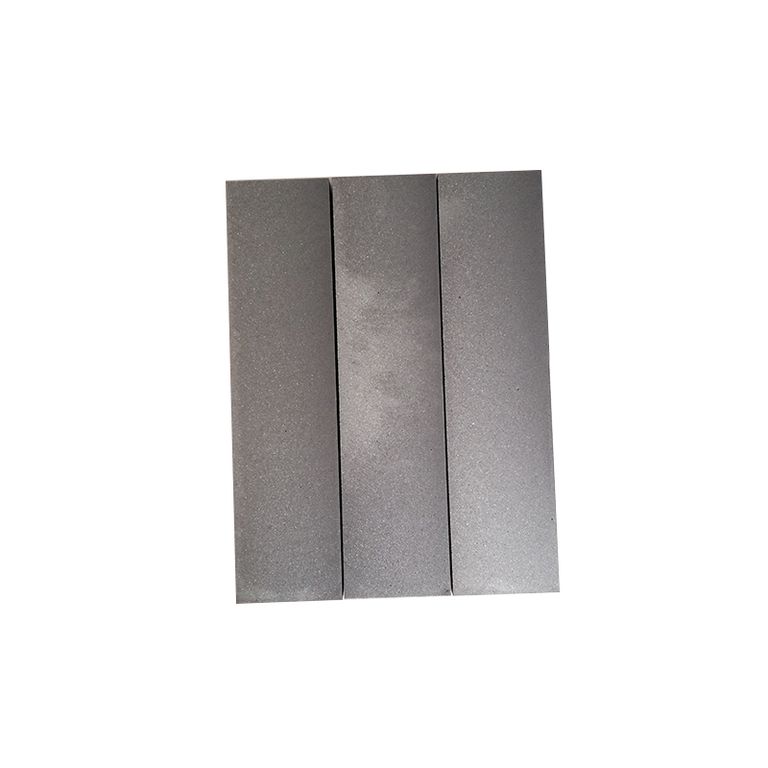

Graphite plate for electrolysis

A graphite plate for electrolysis is a functional carbon electrode material designed for stable current conduction, chemical resistance, and long-term operation in electrochemical systems. In electrolysis processes—where electrodes are continuously exposed to electric current, electrolyte corrosion, and thermal effects—the choice of plate material directly impacts efficiency, service life, and maintenance cost.

Product Description

Graphite plates for electrolysis are manufactured from high-purity, high-density graphite through precision molding or isostatic pressing, followed by high-temperature graphitization. The resulting material features a uniform internal structure, low electrical resistivity, and excellent resistance to chemical attack.

Unlike metal electrodes that may corrode, passivate, or introduce impurities, graphite remains electrochemically stable in many acidic, alkaline, and salt-based electrolytes. This stability is the main reason graphite plates are widely adopted in industrial and laboratory electrolysis systems.

Key Performance Advantages

Excellent Electrical Conductivity

Graphite plates provide low and stable electrical resistance, enabling efficient current transfer across the electrode surface. Uniform conductivity helps maintain consistent current density, which is critical for predictable electrochemical reactions.

In real operation, this reduces energy loss and improves overall process efficiency.

Strong Chemical Resistance

Graphite is resistant to most acids, alkalis, and electrolyte solutions commonly used in electrolysis, including:

Chloride and sulfate systems

Acidic and alkaline electrolytes

Salt and brine solutions

This resistance minimizes electrode degradation and contamination of the electrolyte.

Dimensional Stability During Operation

High-quality graphite plates maintain structural integrity under continuous electrical loading and moderate thermal stress. They resist warping, swelling, and cracking, even during extended operating cycles.

Actually, electrode deformation is one of the most common causes of uneven current distribution—graphite largely avoids this issue.

Long Service Life

Compared with many metal electrodes, graphite plates offer longer usable life in corrosive environments. Reduced replacement frequency lowers downtime and overall operating cost.

Typical Applications

Water Electrolysis

Used in hydrogen and oxygen generation systems as conductive electrode plates or current collectors.

Electrochemical Treatment

Applied in wastewater treatment, electro-oxidation, and electrocoagulation systems.

Electroplating and Surface Treatment

Used as auxiliary electrodes or anode plates in plating baths where corrosion resistance is required.

Chemical and Laboratory Electrolysis

Suitable for research, pilot testing, and small-scale chemical synthesis.

Battery and Energy Systems (Specific Designs)

Used as conductive plates or current distribution components in certain energy-related electrochemical setups.

Standard Specifications (Ordering-Oriented)

Size and Thickness

Graphite plates for electrolysis are commonly supplied in:

Custom-cut rectangular or square plates

Thickness ranges typically from 3 mm to 30 mm

Machined holes, slots, or grooves available upon request

Dimensions are usually defined by cell design and current requirements.

Material Grade Options

Depending on application conditions, customers may choose:

High-density molded graphite

Isostatic graphite for higher uniformity and strength

High-purity graphite for sensitive chemical systems

Suppliers such as Gotrays typically offer machining support to match plate geometry with specific electrolysis cell designs.

Surface and Machining Options

Graphite plates can be supplied with:

Smooth machined surfaces

Grooved or channeled designs to improve gas release

Drilled holes for mounting or electrical connection

Proper surface design can significantly influence gas evolution behavior and current efficiency.

Handling and Usage Considerations

To ensure optimal performance:

Avoid mechanical impact during installation

Ensure uniform electrical contact across the plate

Clean surfaces periodically to remove deposits

Operate within recommended current density limits

In practice, electrical contact quality often matters more than plate thickness.