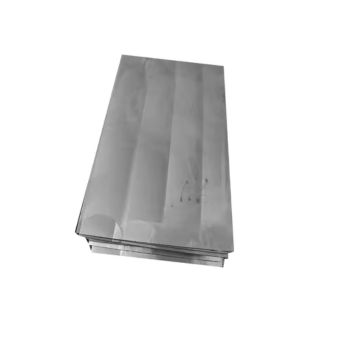

Graphite sheet

A graphite sheet is a flat carbon material engineered for thermal management, sealing, electrical conduction, and chemical resistance across a wide range of industrial applications. Its value lies in versatility: the same material platform can function as a heat spreader, gasket, electrode layer, or protective barrier, depending on grade and structure.

Product Description

Graphite sheets are produced from natural or synthetic graphite through processes such as compression molding, rolling, or exfoliation, followed by controlled heat treatment. The result is a sheet-form material with layered graphite structure, uniform thickness, and predictable physical properties.

Depending on application requirements, graphite sheets may be supplied as:

Flexible graphite sheets

Rigid or semi-rigid graphite sheets

High-purity graphite plates

Laminated or reinforced graphite sheets

Each type serves a different function, but all share graphite’s core advantages: stability, conductivity, and resistance to harsh environments.

Key Performance Advantages

Excellent Thermal Conductivity

Graphite sheets conduct heat efficiently along the plane of the sheet, making them ideal for heat spreading and thermal interface applications. This helps reduce hot spots and stabilize operating temperatures in systems where localized overheating is a concern.

Actually, in many designs, graphite sheets outperform metals on a weight-to-performance basis.

High Temperature Resistance

Graphite sheets remain stable at temperatures exceeding 2,000°C in inert or vacuum atmospheres. They do not melt or soften and maintain structural integrity under prolonged heat exposure.

This makes them suitable for furnace components, thermal shields, and high-temperature gaskets.

Chemical and Corrosion Resistance

Graphite is resistant to most acids, alkalis, solvents, and process gases. Graphite sheets perform reliably in corrosive environments where metals or polymers would degrade.

This chemical inertness is particularly valuable in chemical processing and electrochemical systems.

Electrical Conductivity

Many graphite sheet grades provide stable electrical conductivity, enabling their use in:

Electrodes

Current collectors

Electrolysis systems

EMI shielding applications

Conductivity can be tailored through material selection and sheet density.

Common Applications

Thermal Management

Used as heat spreaders, thermal interface layers, and insulation components in industrial and electronic systems.

Sealing and Gasketing

Applied as high-temperature, chemical-resistant gaskets in piping, valves, and flanges.

Electrochemical Systems

Used as electrode sheets or conductive plates in electrolysis and energy-related applications.

Industrial Furnaces

Used as liners, covers, separators, and shielding plates in vacuum and inert-gas furnaces.

Chemical and Process Equipment

Used where corrosion resistance and temperature stability are required.

Material and Grade Options

Graphite sheets can be supplied in different forms depending on performance needs:

Flexible graphite sheets for sealing and vibration absorption

High-density graphite sheets for structural and electrical use

High-purity graphite sheets for contamination-sensitive environments

Reinforced graphite sheets for improved mechanical strength

Selecting the right structure and density usually has more impact on performance than sheet thickness alone.

Dimensions and Customization

Graphite sheets are available with:

Standard or custom thickness

Cut-to-size dimensions

Machined holes, slots, or profiles

Surface treatments or laminations

CNC cutting and waterjet processing allow accurate shaping without damaging the material.

Handling and Usage Considerations

To maintain performance:

Handle carefully to avoid edge damage

Avoid excessive bending for rigid grades

Store in dry conditions before installation

Clean surfaces gently if required

Flexible graphite sheets tolerate handling well, while rigid sheets require more care.