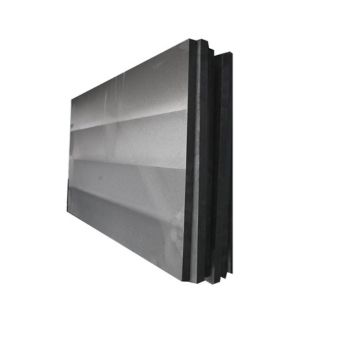

Graphite slide plate

A graphite slide plate is a precision carbon component designed for high-temperature sliding, sealing, and flow-control applications, particularly in metallurgical and continuous casting systems. In environments where metal parts would seize, deform, or wear rapidly, graphite slide plates provide stable movement and reliable service over long operating cycles.

Product Description

Graphite slide plates are manufactured from high-density, fine-grain graphite or graphite-based composite materials through controlled forming and high-temperature treatment. The material combines self-lubricating behavior with excellent thermal stability, allowing smooth sliding motion under load without the need for external lubricants.

In practical operation, graphite slide plates function as wear surfaces and flow-control elements, maintaining dimensional stability while exposed to heat, friction, and mechanical pressure.

Key Performance Advantages

Self-Lubricating Sliding Behavior

Graphite’s layered crystal structure allows easy shear between planes, resulting in naturally low friction. This self-lubrication enables smooth plate movement even at elevated temperatures where oils or greases would fail.

This property is critical in emergency shut-off or frequent adjustment scenarios.

High Temperature Resistance

Graphite slide plates perform reliably at temperatures exceeding 1,000°C in inert or controlled atmospheres. They retain strength and shape during prolonged exposure to heat, making them suitable for continuous industrial operation.

Excellent Wear Resistance

Dense graphite grades resist abrasion and surface damage caused by repeated sliding contact and molten metal splashes. Compared with metallic slide components, wear rates are lower and more predictable.

Thermal Shock Resistance

Rapid temperature changes are common in casting and furnace systems. Graphite’s low thermal expansion helps prevent cracking and warping, extending service life even under aggressive operating conditions.

Chemical Stability

Graphite is resistant to most slags, molten metals, and process gases. This minimizes chemical attack and surface degradation during use.

Typical Applications

Continuous Casting Systems

Used as slide plates in tundish and ladle flow-control mechanisms to regulate molten steel or non-ferrous metal flow.

Metallurgical Equipment

Applied in high-temperature valves, gates, and sliding seals where smooth motion and heat resistance are required.

Furnace and Thermal Processing Equipment

Used as sliding support plates, wear plates, or positioning components exposed to heat and friction.

Industrial Flow Control

Employed in systems where dry sliding under load is required without contamination from lubricants.

Standard Specifications (Buyer-Oriented)

Dimensions and Geometry

Graphite slide plates are typically supplied as:

Rectangular or square plates

Custom-machined profiles

Flat or grooved surfaces

Thickness, length, and width are defined by equipment design. Tight dimensional tolerances can be achieved through CNC machining.

Material Grade Options

Depending on operating conditions, buyers may choose:

Standard high-density graphite

Fine-grain graphite for improved wear resistance

Reinforced or impregnated graphite for extended service life

Suppliers such as Gotrays often match material grade to temperature, load, and sliding frequency, rather than offering a one-grade-fits-all solution.

Service Life Influencing Factors

Slide plate lifespan depends on:

Operating temperature and atmosphere

Sliding speed and contact pressure

Alignment accuracy during installation

Presence of molten metal or abrasive particles

Actually, misalignment during assembly shortens service life more often than material selection errors.

Handling and Installation Notes

For optimal performance:

Handle carefully to avoid edge chipping

Ensure flat, clean contact surfaces during installation

Avoid impact loading during positioning

Follow recommended warm-up procedures

Correct installation often has a greater effect on performance than upgrading to a higher-cost grade.