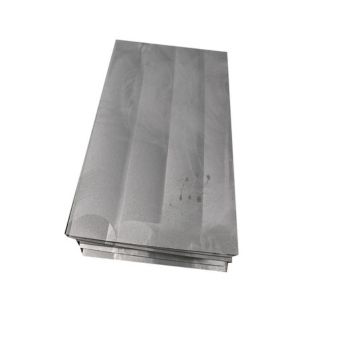

High Purity Graphite Plate

A High Purity Graphite Plate is a precision carbon component engineered for applications where chemical cleanliness, electrical stability, and thermal reliability are critical. It is commonly selected in electrochemical, semiconductor, and high-temperature systems where even trace contamination can affect performance or yield.

Product Description

High purity graphite plates are manufactured from selected graphite raw materials with extremely low impurity content, followed by controlled forming and high-temperature graphitization. Additional purification processes may be applied to further reduce ash and metallic elements.

The result is a dense, uniform graphite plate with stable physical properties and consistently low contamination risk, suitable for long-term operation in demanding environments.

Unlike standard industrial graphite, high purity grades are chosen not for cost efficiency, but for process security.

Typical Purity Levels

High purity graphite plates are commonly supplied in the following ranges:

≥ 99.5% carbon

≥ 99.9% carbon

Ultra-high purity grades available on request

Ash content can be controlled to ≤ 100 ppm, with lower levels achievable depending on specification.

Key Performance Advantages

Extremely Low Impurity Content

Low levels of metal ions and ash reduce the risk of contamination in sensitive processes such as:

Electrolysis and electrochemical reactions

Semiconductor thermal processing

Optical and electronic material manufacturing

In practice, this helps maintain product consistency and reduces downstream defect rates.

Stable Electrical Conductivity

High purity graphite plates provide uniform and predictable electrical conductivity. This is essential for applications involving current distribution, electrodes, or heating elements, where uneven resistance can cause localized overheating.

Excellent Thermal Resistance

Graphite remains structurally stable at temperatures exceeding 2,000°C in inert or vacuum environments. High purity grades maintain this stability without introducing volatile contaminants during heating.

Chemical Inertness

The material is resistant to most acids, alkalis, and process gases. This makes it suitable for aggressive chemical environments where metals or lower-grade carbon materials would corrode or degrade.

Common Applications

Electrolysis and Electrochemical Systems

Used as electrode plates, current collectors, or conductive supports in acidic and alkaline electrolytes.

Semiconductor and Electronics Industry

Applied in heating plates, carriers, and support components where purity directly impacts yield.

Vacuum and High-Temperature Furnaces

Used as structural plates, heat spreaders, or insulation components in controlled atmospheres.

Laboratory and Research Equipment

Preferred for experimental setups requiring stable, repeatable material behavior.

Specialty Chemical Processing

Used in reactors or processing equipment where chemical cleanliness is mandatory.

Standard Specifications (Buyer-Oriented)

Dimensions and Thickness

High purity graphite plates can be supplied as:

Custom-cut rectangular or square plates

Thickness typically ranging from 3 mm to 30 mm

Machined holes, slots, or profiles available

Tight tolerances and flatness control can be achieved through CNC machining.

Material Structure Options

Depending on application requirements, buyers may select:

Molded high purity graphite

Isostatic graphite for higher uniformity and strength

Purified graphite grades for ultra-clean environments

Suppliers such as Gotrays often help match purity level and material structure to the actual operating conditions, avoiding unnecessary over-specification.