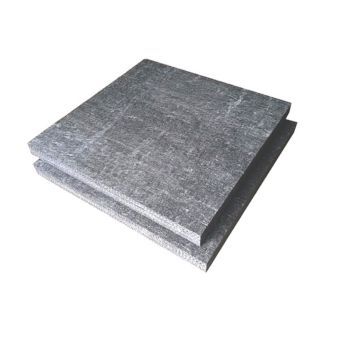

Rigid graphite felt

Rigid graphite felt is a formed carbon insulation material designed for high-temperature structural insulation, combining the low thermal conductivity of graphite felt with improved shape stability and mechanical strength. It is widely used in vacuum and inert-gas furnaces where soft felt alone cannot maintain geometry or withstand installation stress.

Product Description

Rigid graphite felt is produced by compressing and heat-treating graphite felt under controlled conditions, creating a semi-rigid to rigid insulation panel. The process preserves the porous carbon fiber network while increasing density and dimensional stability.

Compared with flexible graphite felt, rigid graphite felt holds its shape during installation and operation. Compared with hard carbon boards, it offers lower thermal conductivity and lighter weight. In many furnace designs, it serves as the ideal middle layer between soft felt and rigid structural components.

Key Performance Advantages

Stable Shape at High Temperature

Rigid graphite felt maintains structural integrity at elevated temperatures, typically:

Up to ~2,000°C in vacuum

Up to ~2,400°C in inert atmospheres

It resists sagging, shrinking, and deformation over long thermal cycles, helping preserve insulation geometry and hot-zone alignment.

Excellent Thermal Insulation

The compressed fiber structure traps heat efficiently while limiting convection. This helps:

Reduce heat loss

Improve temperature uniformity

Lower overall furnace power consumption

In actual furnace operation, stable insulation geometry often matters more than marginal differences in material conductivity.

Improved Mechanical Strength

Compared with soft graphite felt, rigid felt offers:

Better compressive strength

Higher resistance to tearing and abrasion

Easier handling during installation

This makes it suitable for furnace walls, doors, and areas exposed to airflow or mechanical contact.

High Chemical Purity and Stability

Rigid graphite felt is chemically inert to most process gases and resistant to acids and alkalis. Low impurity content and minimal outgassing support clean thermal environments, especially under vacuum.

Physical Characteristics

Typical features include:

Flat panels with controlled thickness

Uniform density across the sheet

Clean-cut edges with minimal fiber shedding

Lightweight compared with rigid carbon boards

The material can be cut, machined, or layered as needed for custom insulation designs.

Common Applications

Vacuum and Inert Gas Furnaces

Used as wall, roof, and door insulation in sintering, brazing, and heat-treatment furnaces.

Hot-Zone Structural Insulation

Applied where insulation must retain shape and spacing around heaters and process chambers.

Semiconductor and Advanced Materials Processing

Used in systems requiring clean insulation with stable geometry at high temperature.

Layered Insulation Systems

Often combined with soft graphite felt, graphite foil, or rigid carbon boards to optimize thermal and mechanical performance.

Laboratory and Pilot Furnaces

Preferred where repeated access and maintenance demand more durable insulation materials.

Standard Supply Forms

Rigid graphite felt is typically supplied as:

Flat sheets or panels

Custom-cut shapes

Multiple thickness options

Density and rigidity can be adjusted depending on insulation and strength requirements.

Installation and Handling Notes

For best performance:

Install with proper mechanical support to avoid point loading

Avoid excessive compression during assembly

Use clean cutting tools to maintain edge quality

Store in dry conditions before installation

Actually, uneven fastening or point pressure is a more common cause of damage than temperature exposure.

Packaging and Logistics

Rigid graphite felt panels are packed flat with protective materials to prevent edge damage during transport. Moisture-resistant packaging is standard, and custom palletizing is available for large furnace projects.

How to Place an Order Efficiently

For fast quotation and correct material matching, buyers typically provide:

Required panel dimensions and thickness

Target operating temperature

Furnace atmosphere (vacuum or inert gas)

Installation location (wall, door, roof, hot zone)

Quantity and delivery schedule

This information allows quick confirmation of density and rigidity grade.